Exquisite OEM for spirits cap factory

Made of high-precision zinc alloy, the surface is processed by multi-layer electroplating

and polishing process,presenting a mirror-like gloss and high-quality texture unique to metal.

- Custom available

Exquisite zinc alloy Liquor caps' Supplier

Zinc alloy die casting offers significant advantages over other materials like aluminum and magnesium alloys, making it an ideal choice for high-precision, cost-effective, and high-performance components.

Zinc alloy is used in luxury spirits bottle caps because it combines high-end texture and practical performance. Zinc alloy is easy to cast with precision, and can create complex details such as coats of arms and logos (such as the embossed bottle cap of Hennessy XO). The surface can be electroplated with materials such as gold and platinum to present a luxurious metallic luster. Its high density brings a calm feel and enhances the sense of opening the bottle. At the same time, it is corrosion-resistant and has good sealing properties, which effectively protects the liquor. Compared with the cheap feeling of plastic or the high cost of stainless steel, zinc alloy achieves the heavy texture and durability required by luxury goods with a moderate budget, becoming the first choice for high-end spirits brands.

Zinc bottle caps for Spirits

- Material advantages: high-density zinc alloy casting, strong plasticity, supports complex shapes and detailed engraving;

- Diverse processes: supports electroplating (gold/silver/rose gold), paint, matte, antique and other surface treatments;

- Flexible customization: LOGO, texture, size can be personalized according to brand requirements;

- Quality assurance: passed the anti-leakage test and wear and corrosion resistance certification, in line with food contact safety standards.

For Italian customers

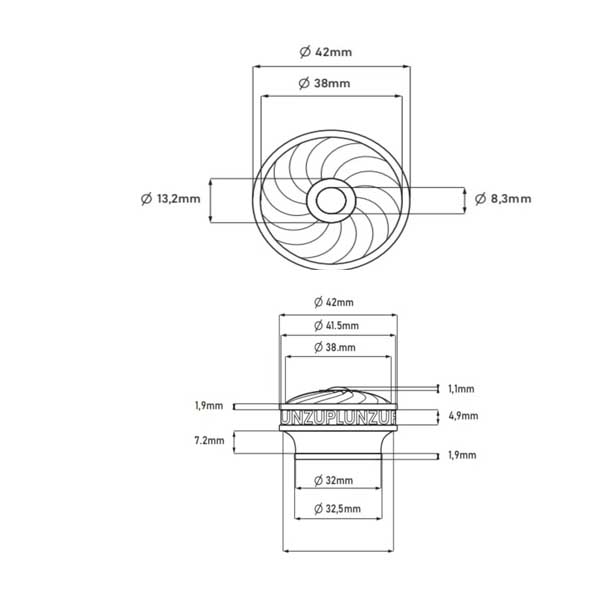

The first customer of liquor bottle caps that 2024 cooperated with was from Italy, a local winery that mainly produces gin rum and grappas. The story begins with a design drawing provided by the customer. The drawing is relatively clear, and it is a spiral structure with a cork.

The customer’s focus has always been on price. He also made it clear that the economy is in a downturn, but he needs to improve the packaging method to increase sales and profits. After understanding his needs, we negotiated 2 sets of solutions. One is plastic material, then spray-painted, obviously the quality does not meet the requirements, and the other is zinc alloy material, electroplated to gold and silver. The customer chose the second set of solutions, and then we started to quote

From the mold fee, to the sample time, to the mass production time, and the transportation method, everything was discussed. After 3 days, it was finally settled. The customer paid the mold fee and it was finally finalized.

related products

Vintage Zinc Closures – Whiskey Decanter Tops

Bulk Zinc Caps – Wholesale for Distilleries

RFID Zinc Caps – Smart Spirit Bottle Solutions

Zinc Alloy Stoppers – Champagne & Wine Seals

Sustainable Zinc Caps – Eco-Friendly Packaging

Heavy-Duty Zinc Closures for Aged Rum/Brandy

Custom Caps with 3D Embossing – Advanced Die Casting Technology